Where can I buy these seals ? thank you.

Had a good read though and some great info.

One question I’d like to ask Joe, (or anyone else who has tried) but when you’ve rebuild shocks with no gas, how did they drive /feel?

To me if they drive okay then I’d be okay rebuilding them with just oil, or maybe even slightly thicker oil for more dampening.

Side question will the ECS system still work OK with lowering springs?

They felt fine to me without any gas. Don’t know anything about lowering springs though.

Thank you Joe once again

Hi Joe - Can I purchase a set of seals?

Any update on this, I am really wanting to keep the factory suspension as it rides really well and handles good (for what I want) when I need it to.

I do not recommend anyone doing modification to their struts because it can have deadly results. That said, this is my first effort at modifying the ecs shock to make it serviceable.

- Tig a threaded collar, careful to apply least heat possible and only to the thicker body part of the outer shock tube.!By the way the collar is threated inside also with very light threads and is screwed on the shock tube with red Loctite which actually fuses them together.

- Making use of the old shock seal so it can provide extra protection to lower new seal from dirt and moisture. Will have to pass the top of the cap on the lathe again to smooth it out.

- Taking care of the low nitrogen pressure refill and maintenance. Will figure out the correct psi 35-40 most probably after the shock is tested on a shock meter. I also think l found the closest match for the existing shock fluid, Maxima Medium #7.5 but also an Amsoil synthetic shock therapy® light #5 suspension fluid can be used.

Cleaned up the old seal which will now function as a dust shield.

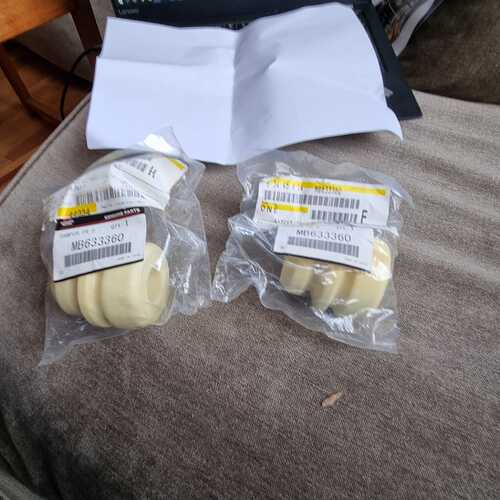

The shock has kept the 35pci nitrogen charge for over one week now. Next will be the shock dyno testing. there is a thread which tells us how to figure out if the shock is in the tour or sport mode setting when it was last disconnected from car. Also received two new shock bumps.

This is the YouTube link: Mitsubishi 3000GT refurbished front ECS shock - YouTube

Hello Joe,

What is your current assessment of rebuilding OEM ECS strut/shocks?

Thanks

Right now, I have too many other projects on the go which are more important. A tool has been designed to re-assemble them but it has not gone into production at this time. Illness has also set a lot of things back by about 6 months. My finances are limited but I will pick this one up in 2022.

Maybe we could get together and do a group buy to cut down on shipping cost? Maybe Joe or another admin would be interested in helping collect the funds and then sending the struts out after they are received, all pre paid of course.

£490 or $650 Each? How much of that was shipping?

It was 350eur a piece and about 200eur shipping&customs.

Thank you. Thats still a bit spendy ($400 usd each) but at least it is an option. Hopefully with 3 different people working on the rebuild idea we might have a solution or at least a possibility soon.

There was a guy out of Canada who was rebuilding struts for the hood and trunk several years ago but I lost his contact information. With my larger than stock spoiler I needed a little extra lift and he set me up with a pair of struts that work like new 10 years later and push my trunk up with almost zero effort.

I would think that someone who does other shocks or struts would be able to come up with something.

Remark: subject was for the rear shocks only… The front ones are not available.

Pascal

Here is a link to the ECS strut wiring and which mode it is in. It maybe helpful with the ESC wiring and other information.

http://renegadetechworks.com/installation/oem-1994-ecs-struts-hardware-2

KYB says most twin tube shocks are pressured to 50 to 100 psi to reduce foaming. See The Differences Between MonoTube & Twin Tube Shock Absorbers - YouTube.

Could we add a gas bag for our rebuild of our ECS Struts? If we did and could how would these perform? This link is of a circle track twin tube rebuild with a gas bag. Rebuilding a QA1 Circle Track Twin Tube Shock - QA1 Tech - YouTube

I have not tried this type of gas bag. I built a small cabinet with a glass window and gloves (similar to a sand blast cabinet). I put the shock inside just before final assembly and fill the cabinet with gas. Did you note that he did not pressurise the tube. I believe that this is the correct method for our shocks but others are reporting 30 - 160psi which is probability bad guesses based on something they see on YouTube or read on a forum. There is many types of shock and a method for rebuilding one type may be completely different to another. As far as I am concerned, nobody should write anything on this subject unless they have actual knowledge on the matter because there is a high risk of serious injury to anyone trying to rebuild the shock, especially at 160psi.

This is the reason that I have not done the final video on shock rebuild until I have unquestionable proof of pressure being used (if any) although I will talk about the method that I use personally and works very well for me.

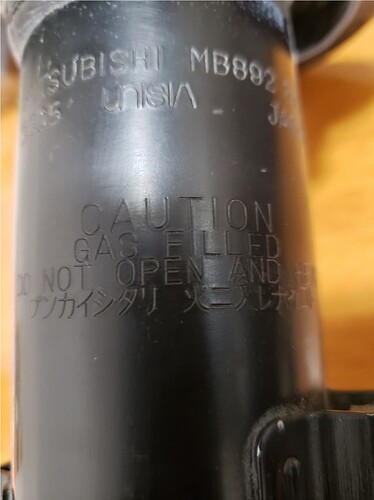

After taking mine on a shock dyno it seems that 25pci works best. The shock started having hysteresis below 10pci.Anything above 30pci l was told would make the shock not function correctly. As for them having nitrogen it is a fact. When new( not old stock sitting for over 20 years) the piston is compressed with some difficulty and retracts upon release. The picture also confirms the presence of gas.