Just thought I´d introduce myself and what I do with one of my GTO’s. I’ve been in the platform since 2011, but tend to only update within our Swedish forum and rarely post on any international forums or fb-groups, but thought it might be fun to share with a few more of you so here’s a brief summary.

As far as we’re aware within our Swedish community - this is the only MR in the country.

Original plans were therefore to keep it mostly untouched, apart from converting it to the JDM/US -99 exterior - a plan that rather quickly went south ![]()

![]()

Bought and imported my MR through a non reserve eBay auction back in 2015 and drove it all the way back home. Once registered and up until august 2016 I had some modifications done to it: -99 headlights, CF -99 sail panels and combat wing, -99 rear center garnish, FMIC, k-sport coilovers, Cianci/C7 Victory bonnet, as well as repainting some of the front subframe and exterior panels, just to mention some of it.

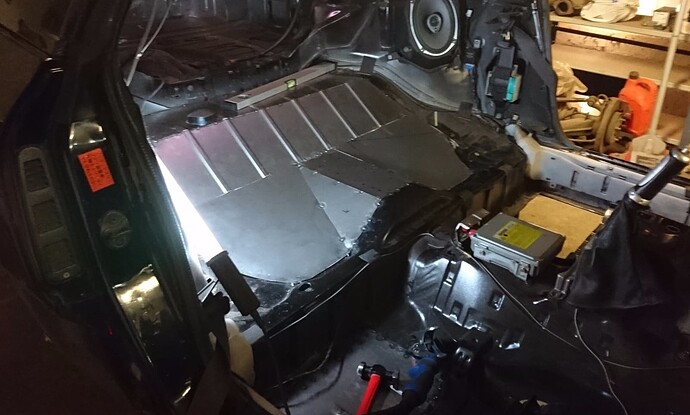

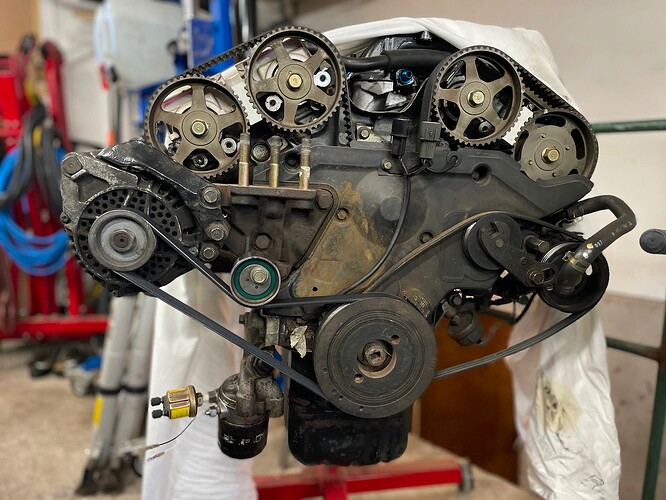

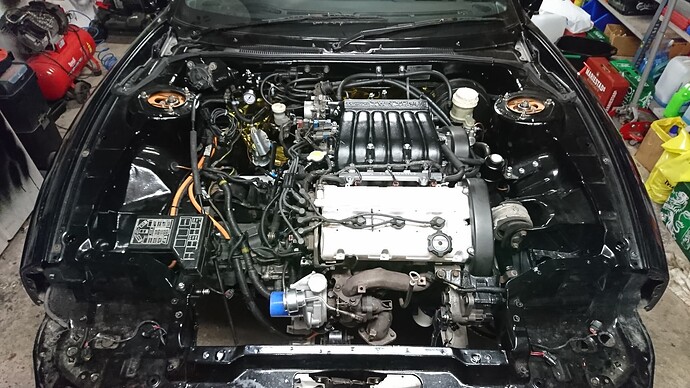

In september 2016 I pulled the drivetrain and stripped the entire engine bay and underside of the car. Found some rust issues in the floor pans and simply decided to cut it all out and have the rear seats permanently deleted, since it’s only registered for two persons anyway. Timing belt was changed along with resealing the transfer, amongst other things and the car was put back together and on the road in May -17.

The same autumn I could finally put the XYZ big brake kit on that had been laying on a shelf for a couple of years, after having sourced a set of 18" Super Advan SA3R wheels from another member in the south of Sweden.

Autumn of -17 until spring / early summer of -18 mostly consisted of modifying the interior and have some performance upgrades done. Seats got replaced for bucket seats on sliders, and I swapped the stock heater system for an aftermarket core which saved me roughly 10kg / 22lbs. Fuel system was upgraded, 16T hybrid turbos put in and the ECU was replaced with an EDM -99 unit that I flashed Chrome software onto.

It pulled fairly hard, despite just being on a rough base map, but at the time I had also saved about 150kg / 330lbs since import - and it clocked in at about 1480kg / 3262lbs with 1/3-1/4 worth of fuel in it.

The same winter I signed up for one of the 2018 time attack series - a journey that ended with me going off the track at about 90-95mph into the grass followed by the sand pit and almost rolling the car.

Since then, it’s been sitting torn apart yet again. Partially because I felt put off emotionally after all time and money spent, but while stripping it I accidentally tore a bolt off of the rear driveshaft mount. I also bought myself a couple of more GT’s - one of which some of you might have seen some pictures of on various fb-groups ( -99 converted widebody gen.1 car with a complete Cianci/C7 exterior, apart from the rear bumper, in a sort of copper/saffron colour).

The project with my MR escalated a bit during this time after a few too many beers and ended with me cutting most of the front end off in an effort of having a bigger radiator fitted since I experienced some heating issues despite running a Mishimoto and a lower temperature thermostat already.

Still working on that setup, nowadays though I have a Toyo radiator that I´ll probably end up fitting in a similar position instead - but have it modified as I’ve already welded AN20 connections to the thermostat housing. I also finally found the encouragement to sort out the issue with the drive shaft mount, cutting/drilling the old ones out and weld it back together.

Rather than my original plans of keeping the car somewhat stock, the idea is to make it a sort of replica out of Pit Road M’s old circuit car - but in a different colour scheme, with other wheels and a different wing. All of which I have laying at home already.

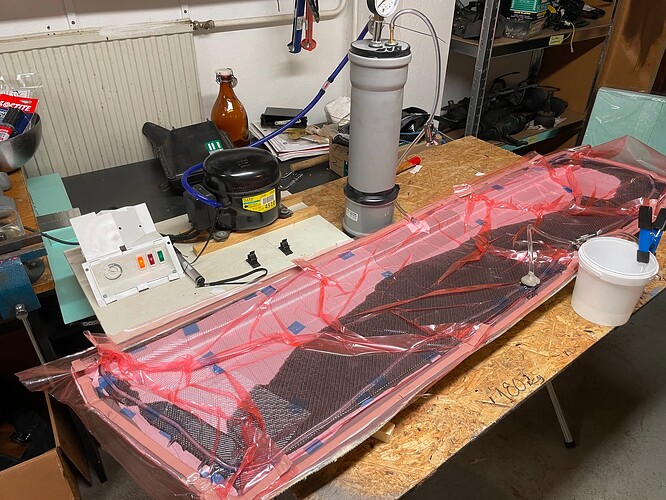

Most of the time otherwise, since I competed in 2018, have been spent on sourcing parts, experimenting with making my own composites parts, having the front and rear subframe with misc parts sent off for industrial sand blasting/paint and making my own seat mounts. Always felt I was sitting higher than stock and too uncentered from the steering wheel with the Bride seat sliders I previously used.

Found a new alternator setup in one of the fb-groups, about a year ago maybe, since I deleted the A/C several years ago I ordered parts to replicate this just to try it out and get rid of the heavy A/C compressor bracket and tensioner which I don’t really need - turned out to be a weight saving of about 4,7kg / 10,4lbs.

Some of the parts that I’ve acquired the past years are the following:

- D2 Racing circuit coilovers with 14kg springs all around

- SuperPro F+R swaybars

- Replica Pit Road M bodykit & Voltex type 7 swan neck wing

- Lightweight König wheels 18x9,5 +35

- AP Racing big brake kit (old 3SX kit, not the factory MR option. Still gave me another weight saving of roughly 3,8kg / 8,4lbs compared to the XYZ kit)

- Evospec billet aluminum diff cover

- OEM option B3H differential

- OEM option carbon cluster surround and titanium shift knob

- Replica decals for the shift knob, B3G and B3H diff’s

- KW Performance SMIS’s

- Euro3S custom floor mats

- JDM/US -99 style third brake light

- -99 combat wing for spare, FG pedestals with CF blade.

- Fluidampr harmonic balancer

I sold 2 out of my 4 GT’s in total last summer, with the intention of hopefully getting my MR back out on the road again in a year or so. Plan is to try and have it rolling by its own sometime this year. Although it probably won’t be roadworthy until 2025 sometime, as the exterior modifications will take a lot of time to complete.

Weight wise, I´m aiming to have it clock in at less than 1400kg / 3086lbs as my next goal - yet being road legal.

Anyway - just felt like sharing a portion of my project and what the future plans look like, perhaps someone finds it interesting ![]()

// Martin